Progressive Cavity Pump Solutions

PCP Fully Integrated Solutions

With over 8,000 PCP installations in multiple countries, we have developed the highest quality standards for designing and automating PCPs for applications ranging from cold, low viscosity oil wells to extremely high temperature, gassy wells. We perform complimentary well simulation/ modeling to evaluate if there is an advantage of installing a PCP solution into any candidate well, and carry out elastomer/fluid compatibility testing (highly critical) at our Houston technology center to ensure optimal pump design for the wells.Our PCP expertise and unparalleled USA built, economic SWC and CILA2S Intelligent Controllers provide the optimal well solution from a small, expanding, and highly adaptable artificial lift based company.

Applications

- High solids production wells

- High GOR or water cut production wells

- Production Rates from 8 BPD - 3,000 BPD

- Well depths to 8,000 ft

- Tubing diameters: 2-3/8" — 6-5/8"

- All well constructions: horizontal, vertical, or deviated

- Operating temperatures up to 350°F with METEOR elastomer

- Low cost and low energy solution

- Can handle large amounts of solids

- Can be installed as a rigless tubing insert or run with the tubing string

- Can be monitored, analyzed, and optimally controlled with the SWC or CILA2S Intelligent Controller and Applications

- Typical 300 — 700+ days pump run life

- Temperature testing up to 200 deg. F

- Pressure testing up to 1,000 psi

- Perform testing with actual reservoir fluids before all installations

- One testing laboratory in Houston, 2 additional in South America

Surface and Downhole Driven Permanent Magnet Motor Solution

We have the only proven controller solution with closed-loop-Flux Oriented Control (F.O.C.) for permanent magnet motor artificial lift systems (Downhole Driven Permanent Magnet Motor PCP's and PMM-ESP's)

+ Power Factor almost 1 at any percentage of load vs. IM

+ Take advantage of the exact amount of current to maximize the torque of the PMM.

+ Sine waveform for PMM in current and voltage

+ Less temperature in cable and motor vs. ESP Systems with IM

+ 5% Additional energy saving of an ESP system with PMM, using a CILA2S ESP Flux Oriented Control.

+ Control in closed loop of current to mitigate control efforts to variations of well load.

+ It allows to flushing the pump without additional equipment

+ It increases the torque capacity and allows smaller motors to handle the system.

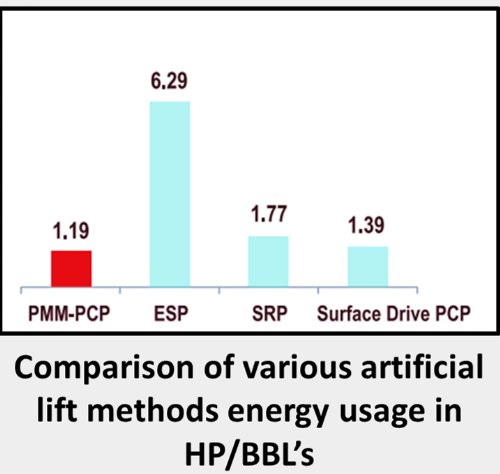

CILA2S ESPCP-PMM Energy Savings

-

At our Houston manufacturing and testing headquarters, we are able to test any ESP or surface/downhole PCP motor (IM/PMM), pump, drive, or sensor for compatibility, software development, and efficiency evaluation. We are able to simulate various loads and electrical sags to validate performance. Please contact us if you would like a tour of the facility or to test a solution and see the advantage of the PMM Flux Oriented Control.

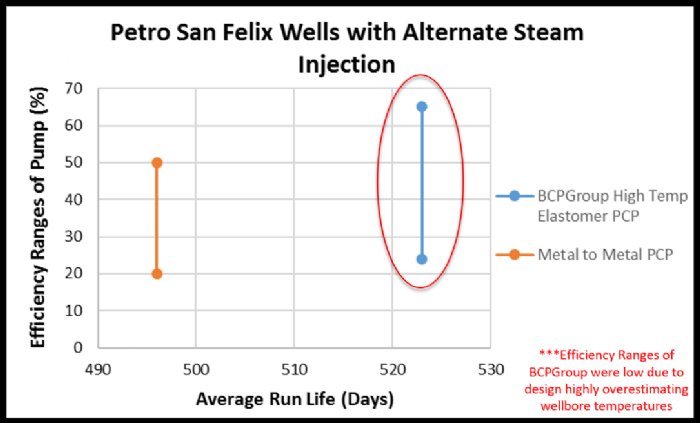

METEOR (Thermal) PCP Solution

The Thermal progressive cavity pump is designed with high temperature elastomers to handle extreme oil well temperatures (up to 360°F operating) and exposure to thermal and combustion processes including cyclic steam injection, magnetic sleeves, or downhole heaters. The use of a high temperature elastomer also allows for better overall pump efficiency and handling of solids than an all-metal PCP solution. A patented specialized rubber and metal adhesion process is also used for the stator of the METEOR (Thermal) PCP.

The Thermal progressive cavity pump is designed with high temperature elastomers to handle extreme oil well temperatures (up to 360°F operating) and exposure to thermal and combustion processes including cyclic steam injection, magnetic sleeves, or downhole heaters. The use of a high temperature elastomer also allows for better overall pump efficiency and handling of solids than an all-metal PCP solution. A patented specialized rubber and metal adhesion process is also used for the stator of the METEOR (Thermal) PCP.

SPE South America High Temperature PCP Solution Study

Venezuelan Oil Company performed a study and presented to SPE on different high temperature PCP solutions and saw our BCPGroup METEOR PCP's outperform the Metal to Metal PCP's in a direct comparison.

Venezuelan Oil Company performed a study and presented to SPE on different high temperature PCP solutions and saw our BCPGroup METEOR PCP's outperform the Metal to Metal PCP's in a direct comparison.

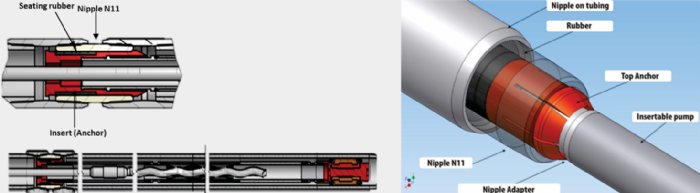

Insertable PCP Solution

This PCP system consists of an insertable PCP lift pump designed with an upper axial anchor to prevent axial movement, and a lower torque anchor to prevent radial movement. It can be easily installed in existing tubing without a workover rig and all maintenance services can be completed with a Flushby Rig.

This PCP system consists of an insertable PCP lift pump designed with an upper axial anchor to prevent axial movement, and a lower torque anchor to prevent radial movement. It can be easily installed in existing tubing without a workover rig and all maintenance services can be completed with a Flushby Rig.

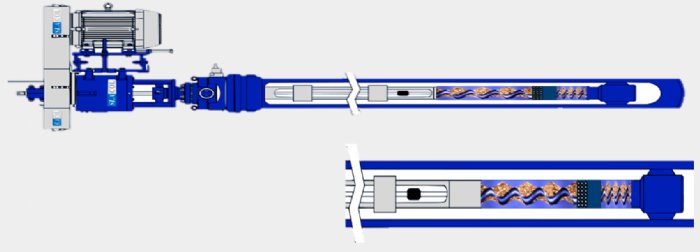

Charge PCP Solution

CHARGE PUMP The Charge progressive cavity pump is designed to handle oil wells with high GOR's and consists of a two array PCP system. The lower PCP is designed with a high displacement and low lifting capacity, while the upper PCP is designed according to the target oil production rate. It is used for oil wells with GOR's above 1,000 scf/bbl and eliminates the need for a gas separator. We have proven experience installing Charge PCP's in wells with GOR's ranging from 800 to 2,000 SCF/BBL.

The Charge progressive cavity pump is designed to handle oil wells with high GOR's and consists of a two array PCP system. The lower PCP is designed with a high displacement and low lifting capacity, while the upper PCP is designed according to the target oil production rate. It is used for oil wells with GOR's above 1,000 scf/bbl and eliminates the need for a gas separator. We have proven experience installing Charge PCP's in wells with GOR's ranging from 800 to 2,000 SCF/BBL.

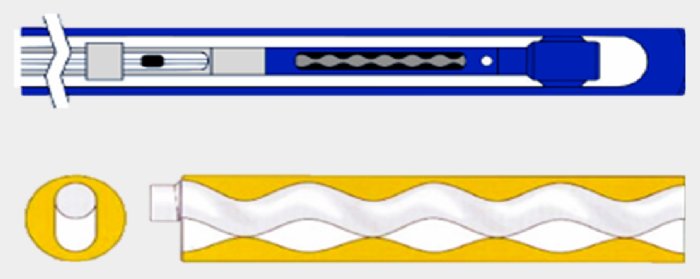

Short-Step PCP Solution

SHORT STEP PCP TECHNOLOGY The progressing cavity pump technology with short step is a PCP specifically designed with shorter stages for wells with heavy crude and high viscosities typically from 8 - 12 deg. API gravity. This pump design will run at lower speeds and higher fill efficiencies than traditional PCP designs.

The progressing cavity pump technology with short step is a PCP specifically designed with shorter stages for wells with heavy crude and high viscosities typically from 8 - 12 deg. API gravity. This pump design will run at lower speeds and higher fill efficiencies than traditional PCP designs.

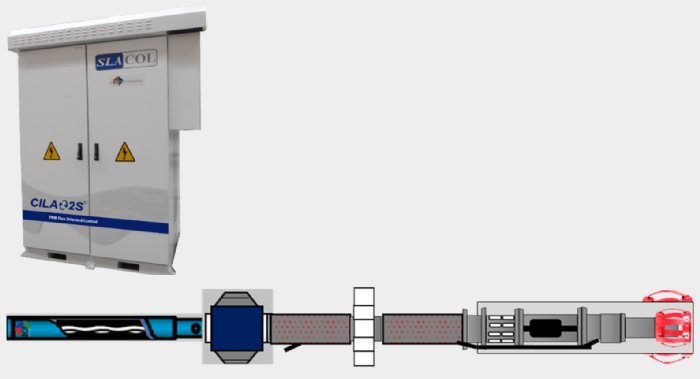

Downhole Heater Solution

METEOR HEATER PCP SYSTEM This system combines a METEOR PCP with a downhole heater below it to handle high paraffin wells. The PCP and downhole heater can be controlled with a single CILA2S that has separate VFD's for controlling the pump and for controlling the heater itself. The temperature can be altered to optimally handle paraffin build-up and increase mobility of the hydrocarbons.

This system combines a METEOR PCP with a downhole heater below it to handle high paraffin wells. The PCP and downhole heater can be controlled with a single CILA2S that has separate VFD's for controlling the pump and for controlling the heater itself. The temperature can be altered to optimally handle paraffin build-up and increase mobility of the hydrocarbons.